What We Do

MotionPort helps engineers achieve better designs by utilizing 3D virtual prototyping technology. This technology, also called simulation, enables you to:

- Reduce physical testing and save money

- Innovate faster and beat your competition

- Keep material costs in check

- Fix your designs before production, not your products after

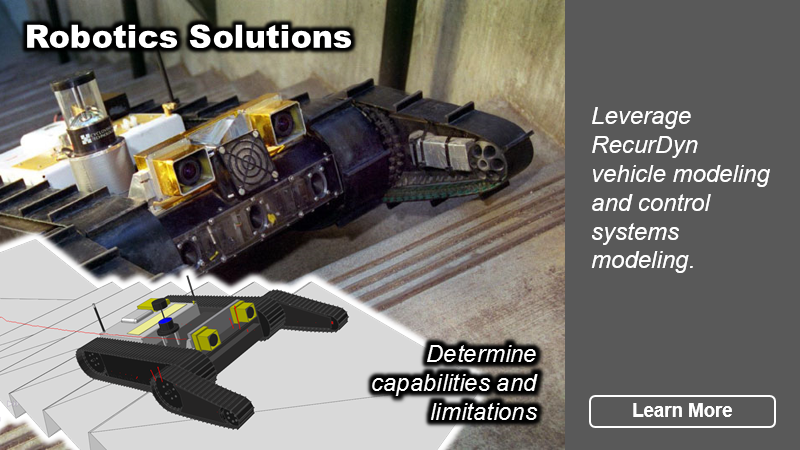

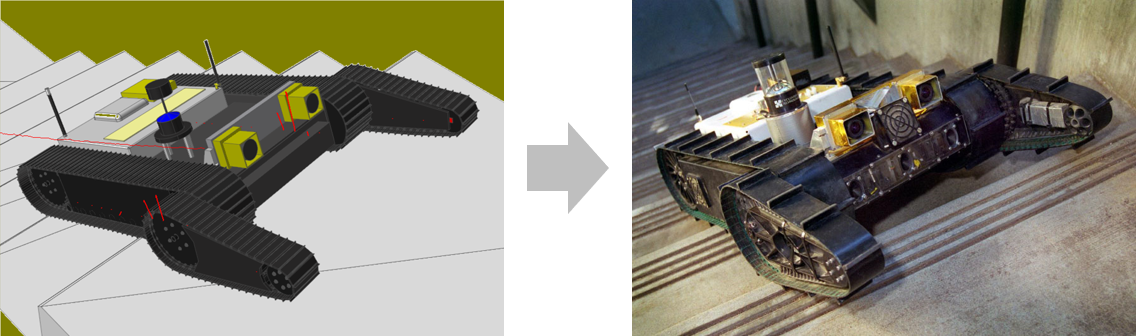

A virtual prototype was used to evaluate the mobility of this tracked reconnaissance robot as it climbs stairs.

Simulation can help you achieve these goals because:

- Simulation-derived information can be obtained before physical prototypes are built

- Simulation-derived information can be measured at locations that are not readily instrumented

- Outputs from a series of design studies can be produced quickly and efficiently

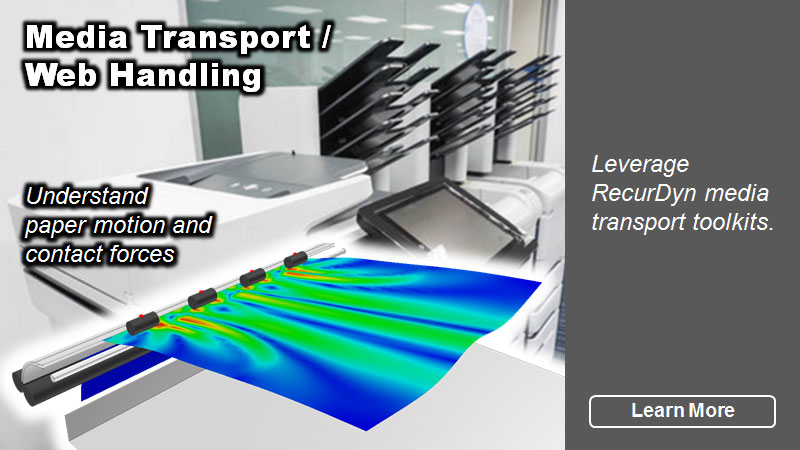

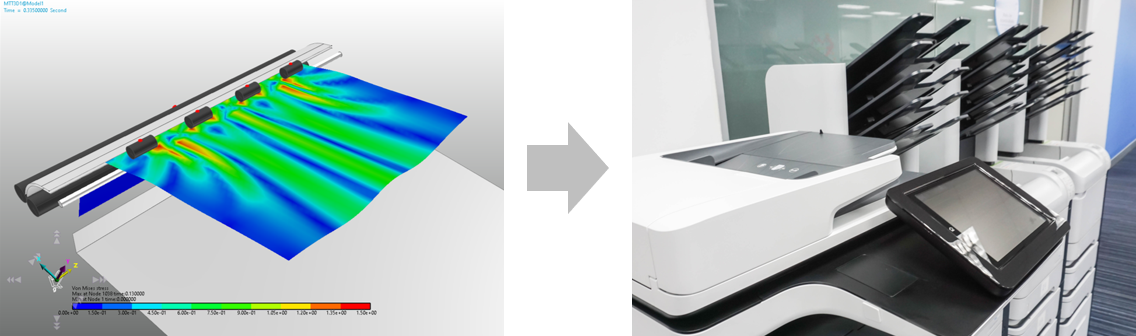

Simulation can be used to improve the design of printers and other mechanical systems transporting flexible media.

Various mechanical Computer Aided Engineering (CAE) approaches can be taken to simulate your systems:

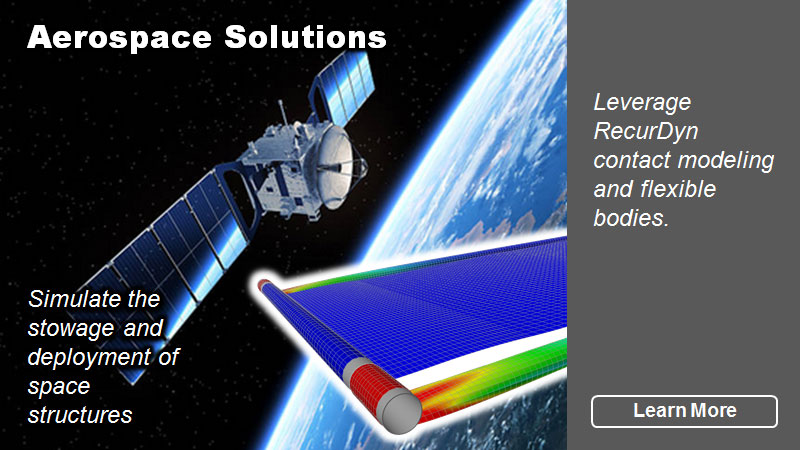

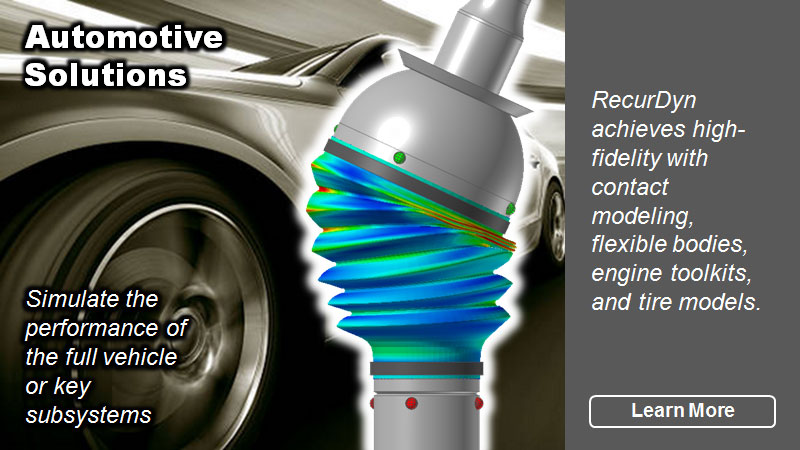

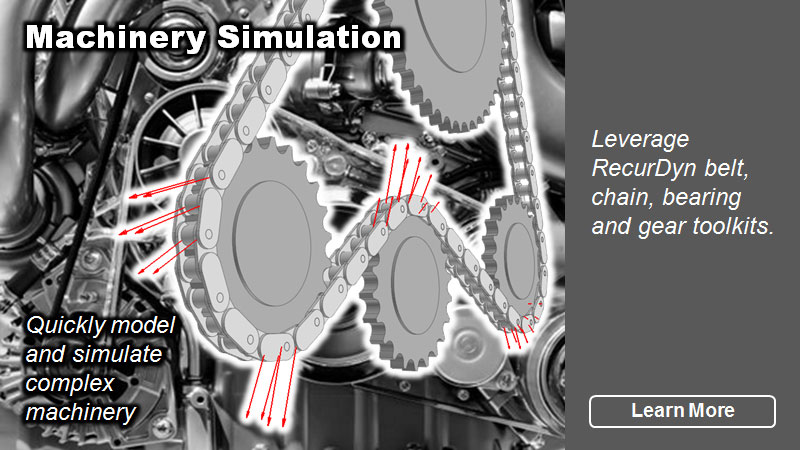

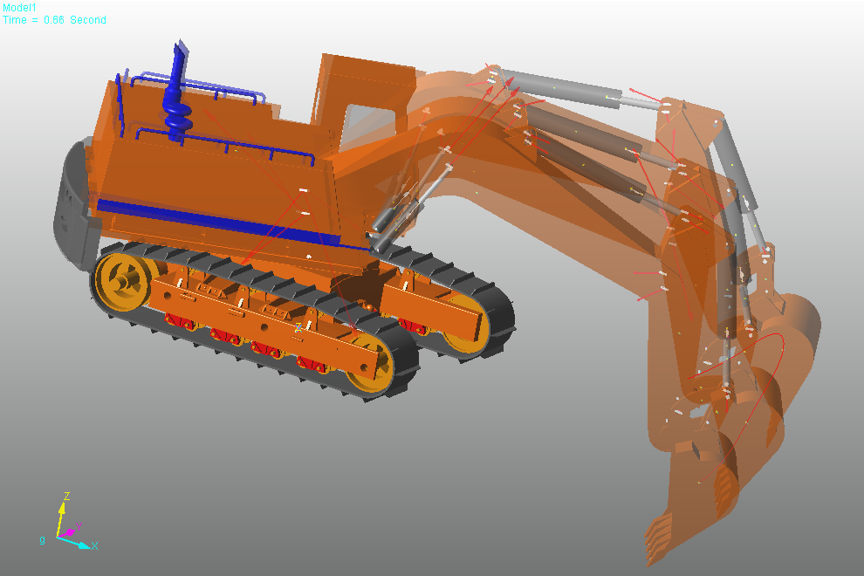

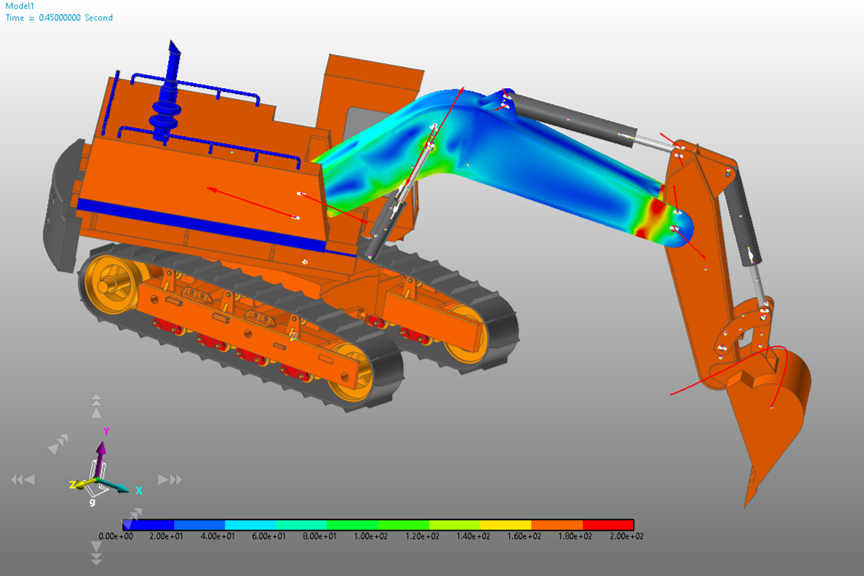

Multibody Dynamics Simulation (MBD) allows you to predict and understand the motion of complex mechanisms.

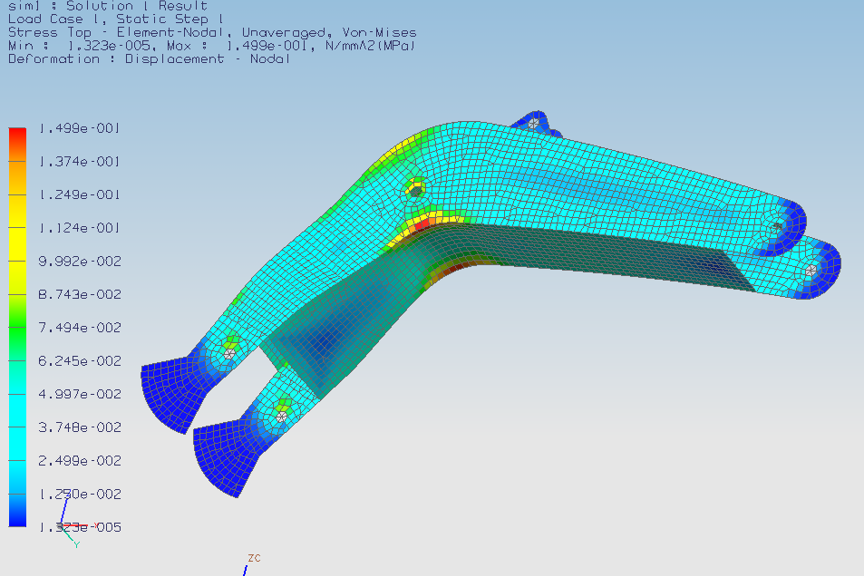

Finite Element Analysis (FEA) enables you to predict and understand how a mechanical component will react under various loads and operating conditions.

Multi- Flexible Body Dynamics (MFBD) is a combined approach that can be taken to increase the accuracy of your simulation results.

We have the knowledge and experience:

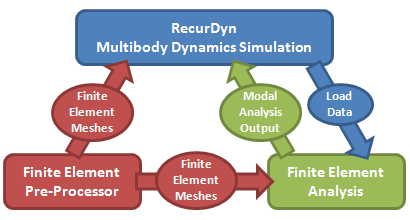

MotionPort recommends the use of various software tools together to perform the simulation types described above, yielding more accurate and useful results:

- RecurDyn Multibody Dynamics Simulation provides loads for use in Finite Element Analysis.

- Finite Element Pre-Processors provide finite element meshes for use in RecurDyn and Finite Element Analysis.

- Finite Element Analysis provides modal analysis outputs to define modal flexible bodies in RecurDyn.

With over 25 years of experience in the field of mechanical computer aided engineering, MotionPort has both the theoretical background and the practical skills required to apply simulation technology to your design challenges.

For more information on the software packages MotionPort uses, please see our partners. Feel free to contact us for more information.