Press Release

FunctionBay and KISSsoft Announce Improved Integration for Simulating the Dynamic Behavior of Gearboxes

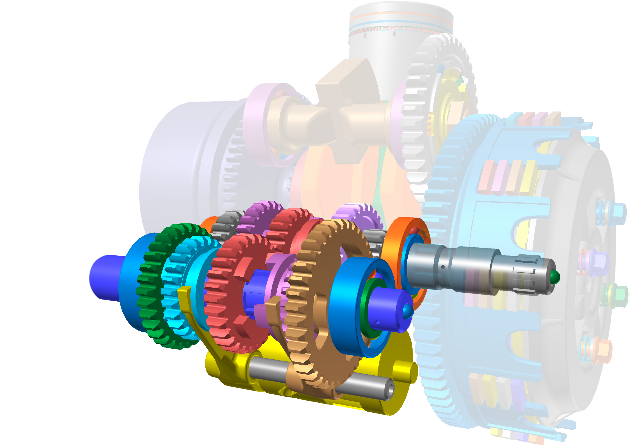

March 9, 2020: FunctionBay and KISSsoft have been working together for several years to combine their resources in a synergistic way. Now, we are proud to present our jointly-developed RecurDyn toolkits called GearKS and BearingKS.

These new products enable engineers to improve the accuracy of their gear and bearing models when simulating the dynamic behavior of gearboxes. This improvement is necessary to achieve current requirements to reduce noise and vibration in transmissions and drive trains. With these two toolkits, RecurDyn can calculate the dynamic transmission error of a complex system, which has been a frequent request from our customers.

RecurDyn/GearKS provides a seamless access to the KISSsoft contact analysis for spur and helical gears. While performing the dynamic calculation in RecurDyn, GearKS determines the forces, moments and stiffnesses relevant for the modeling of gear pairs in each iteration step, based on the well proven model of Weber/Banaschek. The definition of the gear set can be entered either by reading in a KISSsoft file or by using the user interface of KISSsoft, allowing a high level of detail. GearKS also provides a simplified user interface to create the gear pairs in RecurDyn.

With RecurDyn/BearingKS, RecurDyn utilizes the bearing calculation of KISSsoft, which is based on the approach of ISO 16281 BearingKS determines the contact situation of each rolling element in each iteration step. In addition, BearingKS comes with an extensive bearing library of KISSsoft that includes the definition of tens of thousands of bearings, covering 8 global bearing brands and 15 different types of bearings.

Both toolkits come with all of the software needed for the execution in RecurDyn environment, so no external KISSsoft installation is necessary.

Both toolkits come with all of the software needed for the execution in RecurDyn environment, so no external KISSsoft installation is necessary.

“Recently, as customers’ interest in drivetrain increases, many users have requested a high-fidelity gear and bearing solution.” says Michael Jang, CEO of FunctionBay. “Our collaboration with KISSsoft answers those needs and many customers are very interested in these new products. I believe that our new products using the dynamic analysis of RecurDyn and high-fidelity gear and bearing calculation using KISSsoft can bring greater insights, and result in increased design accuracy and reduced prototyping costs.”

Dr. Stefan Beermann, CEO of the KISSsoft company, added: “FunctionBay helps us leverage our technology in areas where we do not have direct access. With the combined competence of the two companies we can create tools that give the engineer a real benefit beyond the current state of the art.”

About RecurDyn

RecurDyn is a Computer Aided Engineering (CAE) software focused on Multi-Body Dynamics (MBD), with extended multiphysics capabilities. The effectiveness of RecurDyn really becomes apparent when approaching large-scale multibody models, including multiple contacts and flexible bodies.

If you want more information about GearKS and BearingKS, you can find them under the info website of RecurDyn/DriveTrain.

About KISSsoft

KISSsoft is a calculation program for sizing, optimizing and verifying designs for machine components such as gears, shafts and bearings, screws, springs, joining elements, belts as well as complete gearboxes. KISSsoft can also be integrated in all popular CAD or CAE programs.

For further information please contact:

Ivana Radmilovic, Head of Public Relations

KISSsoft AG, Rosengartenstrasse 4,

8608 Bubikon, Switzerland

ivana.radmilovic@KISSsoft.AG