Tips for mesh generation – Using the Gradation Factor and Chordal Error Ratio Parameters to Control the Mesh Density

When you mesh complex geometry, you can improve the simulation speed and accuracy by generating a non-uniform mesh, with varying mesh density. The guiding concept is that a higher mesh density should be used in regions of high stress (and high stress gradients) while a lower mesh density can be used in area of low stress (and low stress gradients).

Note: ‘Mesh density’ is defined as the number of elements per unit distance in a mesh. A high mesh density generally produces more accurate results while a low mesh density can be simulated faster.

The RecurDyn/Mesher provides several options to generate a variable mesh efficiently. This article introduces two important parameters, the Gradation Factor and the Chordal Error Ratio. These parameters, when used properly, cause the mesh to have the proper mesh densities at curved surfaces or small features.

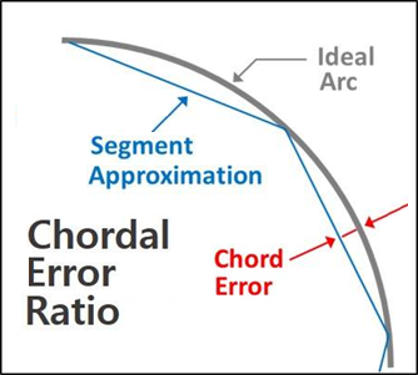

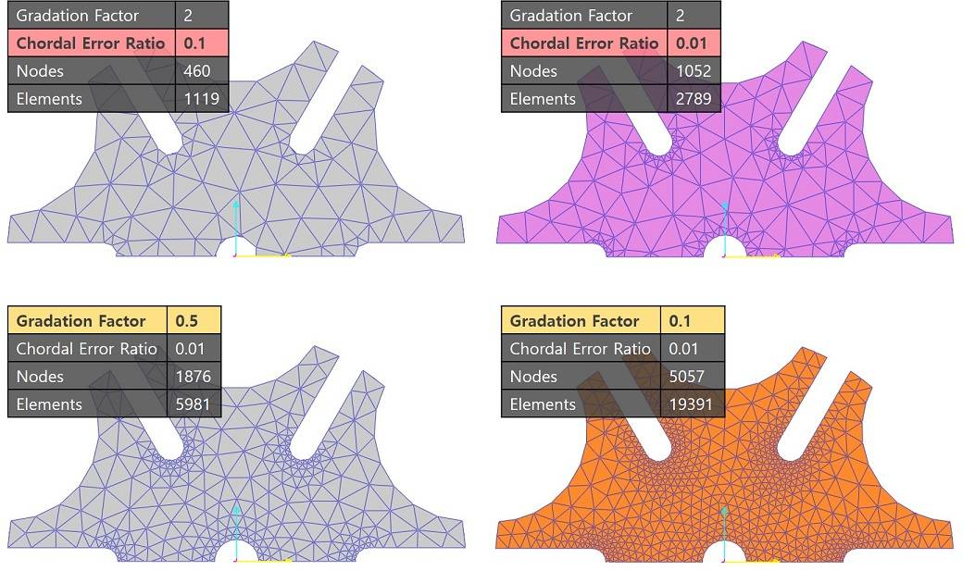

The definitions of the two parameters are as follows (please also refer to the images):

- Chordal Error Ratio: It is the error between ideal curve (arc) and the approximated mesh as compared to the segment length. A smaller value produces a denser mesh on curved geometry that is more accurate.

- Gradation Factor: It defines the rate at which the mesh transitions between high mesh density and low mesh density. The default value is 2. If you use a smaller value, the element size will vary more slowly.

A comparison of the images in the top half of the figure above shows that the reduction of the Chordal Error Ratio by a factor of 10 results in high mesh density along all of the arcs along the perimeter of the Geneva wheel as well as the circle in the center. Then, looking at the images in the bottom half of the figure shows that an 80% reduction of the Gradation Factor results in a much slower transition from a high-density mesh to a low-density mesh.

The best practice is to adjust these two parameters such that the transition in mesh density matches the transition of strain energy in the structure, while keeping the total number of nodes and elements low enough to allow for reasonable simulation times.

In earlier versions of

In earlier versions of